How to evaluate the right membrane switch for any application

The Production Refine Behind Membrane Switch: What You Required to Know

The manufacturing process behind membrane layer changes combines careful style, material selection, and quality control. It begins with comprehending the complexities of membrane layer button layout and proceeds via different stages, consisting of material selections and printing methods. Each phase plays an essential duty in making sure functionality and durability. Nonetheless, the complexities of layer construction and the extensive testing criteria may expose insights that are not promptly obvious. What lies past these fundamental aspects?

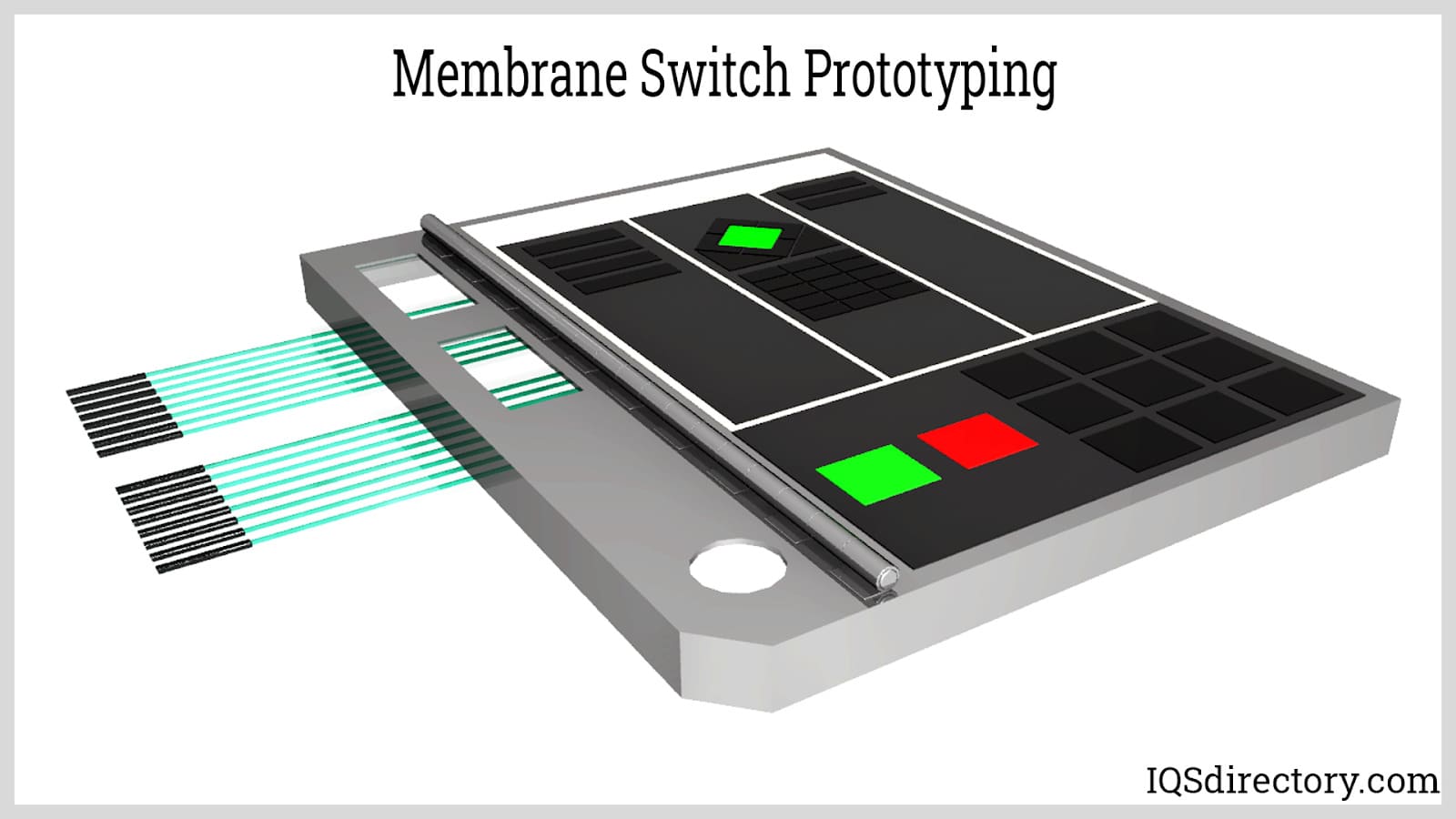

Recognizing Membrane Change Layout

Although membrane switches might show up easy at initial glance, their style entails intricate considerations that ensure capability and sturdiness. The style procedure starts with a thorough understanding of user demands, including the interface's designated application and ecological aspects. Comfort designs is a crucial element, as the layout should help with simplicity of use while guaranteeing that tactile comments meets user expectations.Moreover, the layering of components, such as graphic overlays, adhesive layers, and conductive traces, must be precisely crafted. membrane switch. This split arrangement not just influences the switch's responsiveness but also influences its long life. Focus is provided to the sealing techniques employed to shield versus wetness and dirt, which might compromise performance. Furthermore, layout considerations reach visual appeals, where shade systems and aesthetic clarity enhance customer experience. Inevitably, the style of membrane switches over balances functionality, customer experience, and longevity, making certain that they satisfy the demands of numerous applications efficiently

Materials Utilized in Membrane Switch Over Manufacturing

When picking materials for membrane layer switch manufacturing, it is important to ponder both performance and durability. The key materials consist of polyester and polycarbonate films, which supply flexibility and toughness. These films are usually coated with glue to guarantee appropriate bonding to substrates. Conductive inks, normally composed of silver or carbon, are important for creating electrical links within the switch, enabling for reliable operation.Additionally, a protective layer, such as a tough coat, is often put on enhance scratch resistance and durability. The selection of backing material, such as acrylic or foam, can significantly influence the switch's tactile feeling and total user experience. Furthermore, numerous ecological elements, consisting of temperature level and moisture, should direct product option to assure peak performance in particular applications. Inevitably, the right combination of materials adds to the membrane switch's functionality and lifespan, making informed choices vital for makers.

The Printing Refine: Creating Graphics and Text

The printing process in membrane switch production plays a substantial function in creating top notch graphics and message. Different graphic design techniques are employed to assure aesthetic charm and performance, while cautious ink selection methods are essential for durability and efficiency. Recognizing these aspects is essential for achieving ideal cause membrane switch layout.

Graphic Layout Techniques

Graphic design methods play an important duty in the printing process of membrane buttons, as they define exactly how graphics and message will inevitably appear on the final item. Effective graphic style entails the tactical usage of layouts, font styles, and shades to boost readability and aesthetic appeal. Designers typically make use of vector graphics for scalability, ensuring that images remain sharp at different sizes. Furthermore, focus to comparison and placement is vital, as it influences user interaction and aesthetic quality. The consolidation of branding aspects, such as logos, should be managed with care to preserve brand integrity. In general, thoughtful graphic design techniques contribute considerably to the functionality and attractiveness of membrane layer buttons, influencing individual experience and product performance.

Ink Selection Methods

Picking the ideal ink is crucial for attaining the wanted visual quality and resilience in membrane button manufacturing. Various ink types are made use of, consisting of solvent-based, water-based, and UV-curable inks. Each type offers distinctive attributes, such as resistance, adaptability, and bond to environmental variables. Solvent-based inks are commonly favored for their durability and lively colors, while water-based inks are extra eco-friendly however may have restrictions in adhesion. UV-curable inks supply rapid healing and robust efficiency. Additionally, shade matching techniques ensure that the selected inks line up with layout specs. Inevitably, the choice of ink have to consider aspects such as application method, substratum compatibility, and end-use needs to achieve remarkable results in membrane layer button graphics and text.

Layer Building and Setting Up

Product Selection Process

A cautious option of products is important in the production procedure of membrane layer switches, as it directly influences performance and durability. The primary materials utilized consist of polyester, polycarbonate, and numerous conductive inks. Polyester is often favored for its outstanding resistance to chemicals and abrasion, making it appropriate for extreme settings. Polycarbonate, on the various other hand, provides superior clarity and effect resistance, which is useful for applications calling for presence and effectiveness. Conductive inks, typically made up of silver or carbon, are vital for creating dependable electrical pathways. Additionally, the selection of glue products influences the general stability of the switch - membrane switch. Assessing elements such as environmental exposure, responsive responses, and visual demands guides manufacturers in picking the ideal products for their particular applications

Layer Adhesion Techniques

Sticking layers in membrane layer switch construction is a vital procedure that assures performance and longevity. Numerous attachment methods are employed to safeguard suitable bonding between layers, which typically consist of using adhesives, heat, and stress. Pressure-sensitive adhesives (PSAs) are typically utilized for their convenience of application and instant bonding capacities. Furthermore, thermal bonding techniques can be used, where heat is made use of to trigger glue buildings, protecting a strong bond. The option of adhesion technique largely depends upon the materials included and the specific application demands of the membrane layer switch. Correct alignment and uniform application of adhesives are vital to stop issues, protecting the button operates successfully throughout its desired life expectancy.

High Quality Control Actions

Guaranteeing quality assurance throughout the layer construction and assembly of membrane layer buttons is important for preserving efficiency and reliability. This process normally entails several vital actions, consisting of comprehensive assessments at each phase of manufacturing. Manufacturers utilize sophisticated testing techniques, such as peel examinations and attachment analyses, to validate the integrity of layer bonds. Additionally, visual evaluations are carried out to determine any type of flaws in printing or product variances. Ecological problems, such as temperature level and moisture, are very carefully kept an eye on to ensure suitable healing wikipedia reference and attachment. Normal calibration of tools assists preserve accurate manufacturing standards. By applying these top quality control procedures, makers can considerably decrease the risk of item failing, guaranteeing that the last membrane layer changes meet the called for specs and customer assumptions.

Checking and High Quality Control Measures

Innovations in Membrane Change Innovation

As innovations in modern technology remain to develop, membrane switches are taking advantage of ingenious growths that boost their capability and customer experience. One notable innovation is the integration of capacitive touch technology, which enables for more intuitive and responsive interface. This shift not just improves visual appeals but also reduces mechanical wear and tear, extending the life-span of the switches.Additionally, innovations in visuals overlay products have led to improved durability and resistance to ecological variables such as wetness and UV light. These materials now supply boosted clearness and brightness, more boosting the visual appeal.Furthermore, the incorporation of clever innovation is transforming membrane layer changes into interactive control board, allowing connectivity with IoT tools. This connectivity fosters a smooth user experience, leading the method for applications in various sectors, from health care to customer electronics. Collectively, these advancements position membrane layer changes as critical elements in modern gadget design.

Regularly Asked Questions

For how long Does the Membrane Layer Switch Manufacturing Refine Take?

The duration of the membrane layer switch manufacturing procedure can vary significantly. Factors such as intricacy, products used, and manufacturing volume influence timelines, with regular production ranging from a couple of days to several weeks for completion.

What Are the Common Applications for Membrane Layer Switches?

Membrane layer switches are generally made use of in different industries, consisting of vehicle controls, family home appliances, medical devices, and consumer electronics (membrane switch). Their flexibility and longevity make them perfect for applications calling for easy to use interfaces and reliable efficiency in diverse environments

Can Membrane Changes Be Customized for Certain Needs?

What Is the Life-span of a Normal Membrane Change?

The life-span of a common membrane switch varies, yet typically, it ranges from 1 to 5 million cycles. Factors such as usage, environment, and worldly quality significantly influence toughness and overall efficiency with time.

Are Membrane Layer Switches Eco-friendly?

The environmental friendliness of membrane layer switches varies. Some materials utilized may not be recyclable, while others can be green. The general effect relies on producing products and practices, necessitating careful factor to consider throughout choice and disposal. The production procedure behind membrane switches over combines cautious style, product selection, and quality control. It begins with understanding the ins and outs of membrane switch design and proceeds via various phases, consisting of product selections and printing techniques. When picking materials for membrane layer switch manufacturing, it is vital to ponder both performance and longevity. A cautious choice of materials is important in the production process of membrane buttons, as it directly influences performance and durability. The selection of bond approach mostly depends on the products entailed and the specific application demands of the membrane button.